5 Reasons to Choose Galvanized Steel

Steel on its own is a very ductile and strong metal that is capable of withstanding great strain. It can also be manipulated into various shapes and forms making it a very reliable and convenient solution. However, as most of what it is used for is outdoors, i.e. Structural parts in construction, automotive chassis and components, tools, security, storage, clean energy and general aesthetic appeal; it is exposed to the elements. This means weathering and corrosion in the form of rusting. This can be quite expensive to maintain and can turn into a public safety hazard as well.

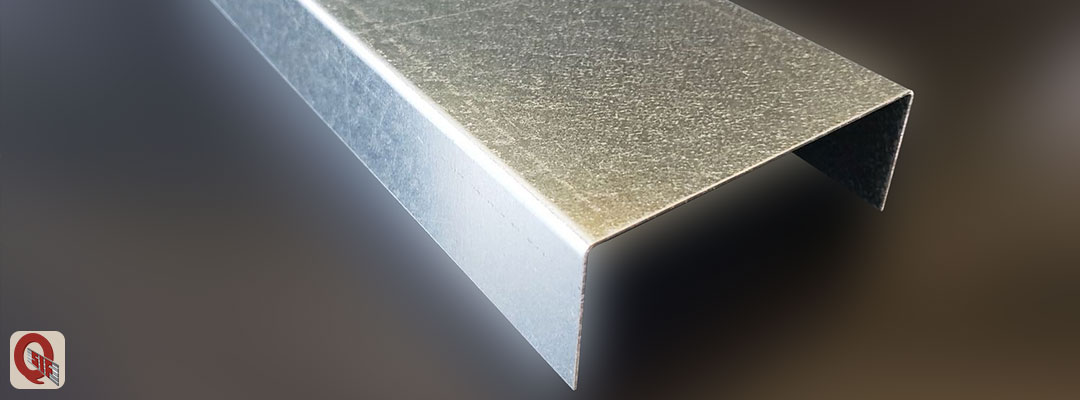

The solution is galvanization - specifically hot-dip galvanization, which is reliable, efficient and cost-effective. The process is quite straightforward and involves firstly the treatment of a metal, where it is cleaned chemically to remove any impurities and prepare it for the dipping process. The next and main step is where the treated metal is dipped in hot molten zinc, which forms a metallurgical bond with the metal. On removal, the zinc reacts with the oxygen in the environment to form zinc oxide. This then further reacts with carbon dioxide to form zinc carbonate. This final form gives the metal the spangle matt sheen for which it is known.

So why galvanizing? Seems like an expensive process. Didn’t luxury car brands use this method? Is it even practical? I bet a few scratches and the whole process becomes redundant. Well here are 5 reasons that will put all these fears and more to rest:

Cost-Effective, Reliable and Quick

The process of galvanizing is a Hail Mary for steelmakers and consumers alike. It takes treated metal and dips it into hot molten zinc that is alloys to it. It forms a protective layer that is strong and metallurgical in its bond. As it is dipped, whether it be hollow or one uniform surface, the zinc reaches each point of the surface area, leaving nothing exposed. Meaning you have ensured a complete coating that meets industrial standards.

The turnaround is also quite quick with most well-known brands like ours: Qatar Steel Industries Factory completing the process effectively within 24 hours. From the protection to the usage, the product is quite cost-effective. Studies have shown that paint coating not only requires more frequent maintenance but also increases in cost with time. Whereas single-coat zinc lasts for up to 60 years. Furthermore, the coated Steel requires little to no maintenance at all.

Sturdy and Tough

Galvanized steel is very tough on multiple levels as the bond between zinc and iron is on a metallurgical level. This means the coating forms a very strong protective layer that is not only corrosion-resistant but also chip resistant.

That means the product remains intact and untarnished during assembly and construction, followed by exposure to the elements and time.

Easy to monitor

The coating across galvanized surfaces is uniform and can easily be measured for its consistency. That also applies to the weathering and corrosion effect on the surface with time.

Without destructive methods, the coating can be measured for degradation over time quite easily. Accurately measuring its effectiveness and its reaction to various environmental conditions.

It is Sustainable

The benefits of galvanized steel are that it’s long-lasting and retains its aesthetic appeal for quite a long time. The strong coating protects it effectively against physical damage and zinc against corrosion and weathering.

This means the cost of maintenance of public projects is little to nothing, freeing up budgets for other areas of development and infrastructural needs.

What you see is what you get

The coating forms a bond that is on a metallurgical level. That means that no failure occurs in the layer underneath. The usual coatings adhere to an environmental residue that compromises long term performance, causing flaking and failure.

Galvanized steel however experienced no such issues. What you see is bright sheen turned to a duller patina that is formed due to exposure to the elements. This in turn strengthens the layering further by forming a stronger and more complex protective layer with the zinc.