The Benefits of Laser Cutting in the Manufacturing Industry

About The Advantages of Laser Cutting in the Qatar Steel Industry

This blog could discuss the various benefits of laser cutting in the manufacturing industry, including its precision, speed and versatility. It could also explore how laser cutting technology has evolved over the years and how it is being used in different industries.

Introduction

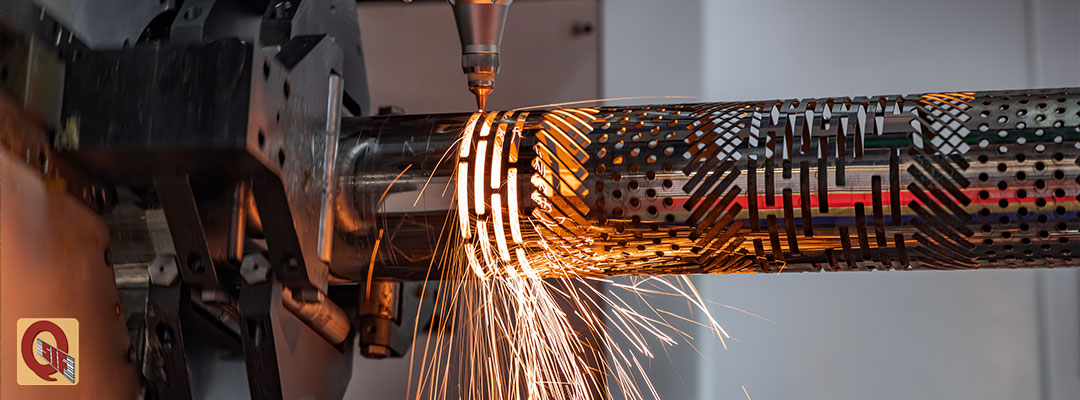

Laser cutting is a technology that uses a focused laser beam to cut through materials, such as metal, plastic and wood. It is a highly precise and efficient method of cutting, and it offers several benefits over traditional cutting methods.

Benefits of Laser Cutting

One of the main benefits of laser cutting is its accuracy. Laser cutting machines can produce cuts with a high level of accuracy and repeatability, making it ideal for producing parts with tight tolerances. Additionally, laser cutting can produce clean and smooth cuts with minimal burrs or other imperfections. This is especially important in industries such as aerospace, medical devices and automotive, where correctness is important.

Another benefit of laser cutting is its speed. Laser cutting machines can cut materials at a much faster rate than traditional cutting methods, such as mechanical cutting or waterjet cutting. This makes laser cutting an efficient choice for high-volume production, as it can significantly reduce production times and increase productivity.

Laser cutting is also a versatile technology that can be used to cut a wide range of materials including metals, plastics and wood. This makes it an ideal choice for a variety of applications, from automotive parts to medical devices. The ability to cut a wide range of materials also makes laser cutting a cost-effective solution, as it can reduce the need for multiple cutting machines or processes.

In addition to its accuracy, speed and versatility, laser cutting also has a number of other benefits. It can produce minimal waste, as the laser beam can be focused on the exact area to be cut, reducing the amount of material that needs to be discarded. Laser cutting also generates minimal heat-affected zones (HAZ), which can minimize the risk of material distortion or other issues.

Conclusion

Laser cutting has come a long way since it was first introduced in the 1960s. Today's laser cutting machines are more advanced and efficient than ever, with improved accuracy, speed and versatility. As the technology continues to evolve, it is likely that laser cutting will become even more widely adopted in the manufacturing industry.