Thanks for downloading catalogue.

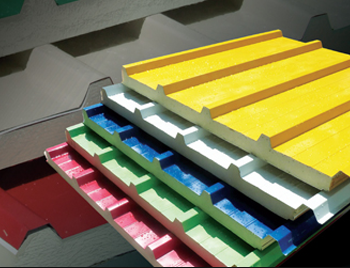

Double skin sandwich panels come as pre-painted galvanized metal panels on the Top and Bottom that are adhered to a thick layer of Polyurethane. Like its single skin cousin, Polyurethane retains its fire retardant and sound dampening properties. Ensuring that the structure is not only safe from fire hazards but allows for little to no sound to enter and exit as well.

For clients seeking to build storage units, Cabin, or even Cooling units for sensitive goods and perishables, residential, industrial and commercial projects can use Qatar Steel Industries Factory’s Double Skin Sandwich panels to great effect. This variant, unlike its single skinned cousin, has a thicker layer of Polyurethane foam with a Top and Bottom PPGI layer being called a “Sandwich” Panel. The options on hand vary from 30mm to 100mm as opposed to the 20mm that you get on the single skin sandwich panel.

Projects for areas where extreme weather conditions persist such as extremely wet and humid, hot or cold, or more, the double skin sandwich panel takes center stage. Due to double the thickness of Polyurethane, the internal environment of the structure, whether it is for storage or general living, exists within ideal conditions.

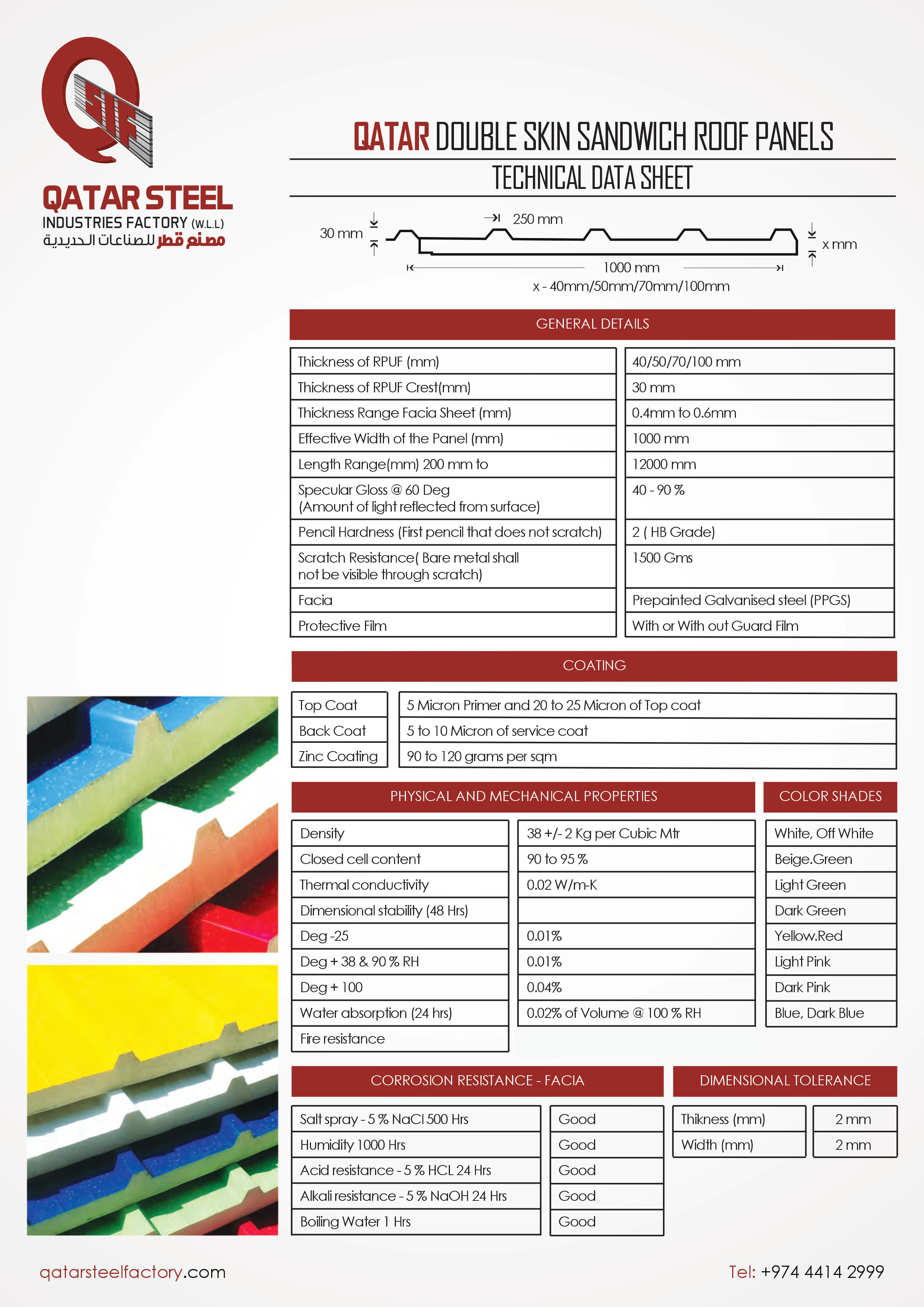

Size, Dimensions and Coating:

- The Thickness of panels ranges from 0.4 - 0.6 mm, the added foam crest thickness is 30 mm and the foam thickness itself ranges from 40 - 100 mm.

- Panel Width is 1000 mm.

- Length range is from 200 to 12000 mm.

- A scratch-resistant surface that is coated up to 1500 gms.

By investing in a Qatar Steel Industries Factory Double Skin Sandwich Panel, you get:

- A high quality and cost-effective solution that is strong and very durable. Ensuring long life and low maintenance.

- A product that easily accommodates projects which are on a strict timeline. The easy to assemble and portable nature of these panels allow for quick installation.

- A solution that safeguards against all weather conditions be it extremely hot, humid or cold

- A Polyurethane pressed galvanized panel that protects against fire hazards giving you the peace of mind that you rightfully deserve when storing your assets.

- A wide selection of paint colors to choose from to accommodate your aesthetic requirements for your project.