Thanks for downloading catalogue.

At Qatar Steel Industries Factory KWIK roofing sheets are made from Pre-painted galvanized sheet metal panels that are passed through a radius-bending machine. These sheets are curved or bent in two ways: natural and machine. For the natural methodology, the sheet is placed on a radius over a large surface area that bends with its own weight. The machine method is majorly used for tighter radius where a galvanized metal sheet is placed in a bending machine that stretches and compresses till the metal reaches its desired state.

The galvanic nature of the sheets ensures that they are corrosion free and rust free. The curved nature of the sheets allow for heat dissipation and can withstand extreme temperatures. It is also lightweight, allowing for ease of mobility and installation.

At Qatar Steel Industries Factory, each sheet is thoroughly inspected and undergoes the rigors of quality checks. All meeting the highest of standards in the market and ensuring that each client receives only the best. Demand for this product is quite high as they are quite visually appealing and fit well with the façade of the structure. A few notable areas of application are water tanks, aircraft hangers, sheds, barns, tunnel cladding and poultry housing.

With the purchase of KWIK roofing sheets, you get:

- A high quality product that is corrosion and rust free as well as durable and strong as it underwent the process of galvanization.

- Resistant to weathering and extreme conditions.

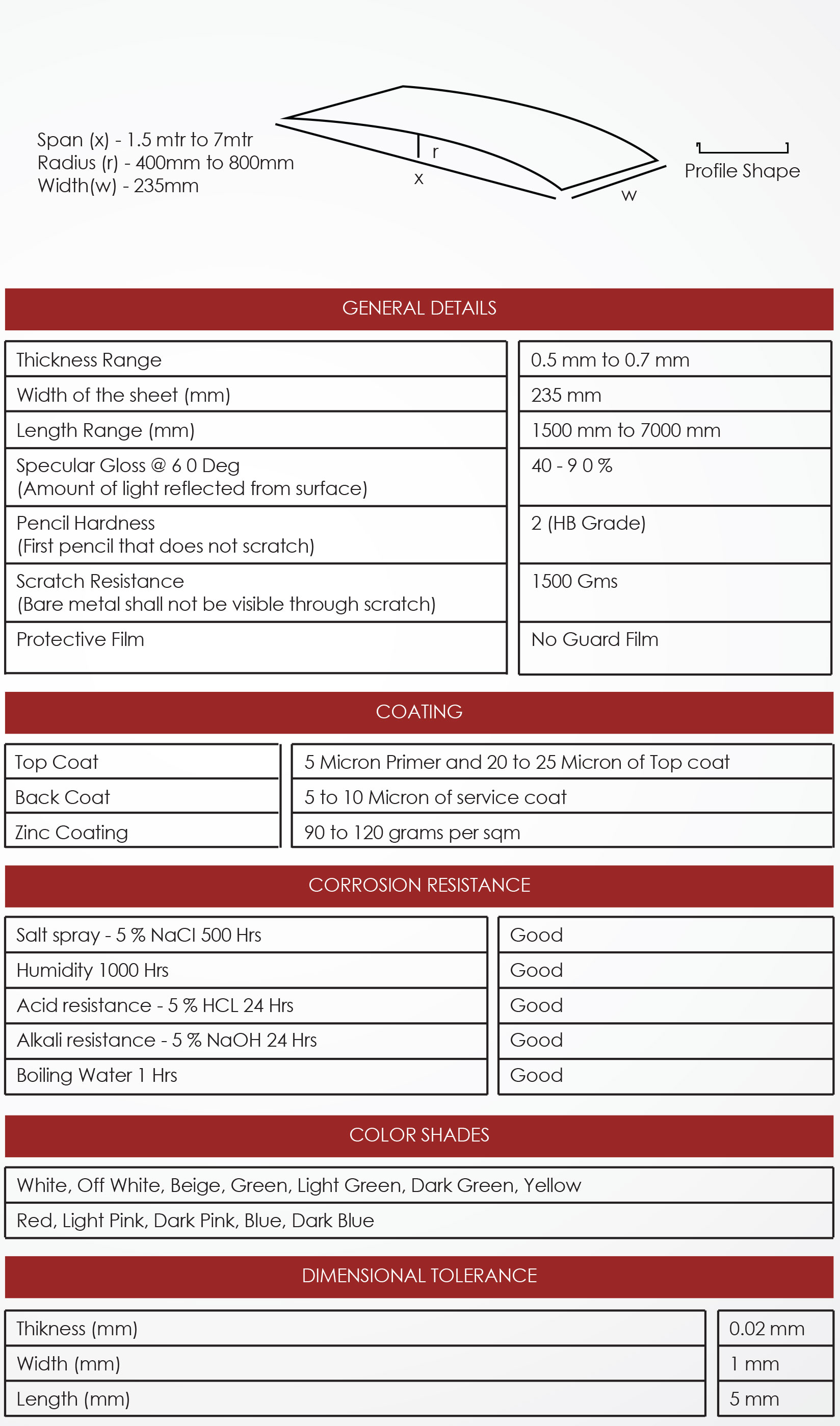

- Options for thickness varying from 0.5 to 0.7 mm, width 235 mm and a length range of 1500 to 7000 mm.

- Wide selection of paint options that fit your customization needs.

- Lightweight and cost effective as its portable, easy and quick to install.

- Little to no maintenance cost which contributes to a longer life span.

- Scratch resistant for up to 1500 gms.

- Dimensional options in thickness ranging from 0.5-0.7 mm, width of 235 mm and length ranging from 1500-7000 mm.

- Coating ranges divided into Top ranging from 5 Micron Primer and 20-25 Microns of top coat, Back ranging from 5-10 microns service coat and finally zinc ranging from 90-120mm grams per sqm.