Thanks for downloading catalogue.

Round tubing (CHS) or round structural pipes are cylindrical shaped that are hollow. They have a wide variety of structural and architectural applications. These tubes are measured by their outside diameter and their wall thickness. Some examples of round tube applications would be commercial and residential structures, storage systems, and construction of bridges, support columns, guardrails, furniture and automotive parts.

To attain these round hollow tubes one can use either hot or cold rolling processes. The hot rolling process involves rolling the metal at a high temperature, which is above its recrystallization temperature. At this temperature and in this malleable state, it can be shaped and formed easily, leading to much larger sizes.

When hot rolled metal undergoes further processing, it is then known as cold rolled metal. The metal is cooled down to room temperature followed by tempers rolling. This process results in metal, which has closer dimensional tolerances and a wider range of surface finishes.

The term Cold Rolled is erroneously used for products, when in actuality the product name refers to flat rolled sheets and coil products. All cold rolled products provide a superior surface finish, tolerance, high strength and straightness when compared to hot rolled.

When procuring Qatar Steel Industries Factory ERW CHS (Circular Hollow Section) or round hollow structural solutions know that:

- The product is lightweight, durable, strong and cost effective.

- The surface of the product will have a superior finish.

- The processes from manufacturing leading up to the finished product follows the strict quality control guidelines set by the industry namely ASTM A500 Standards.

- All products are designed to specifications; fulfilling your requirements exactly.

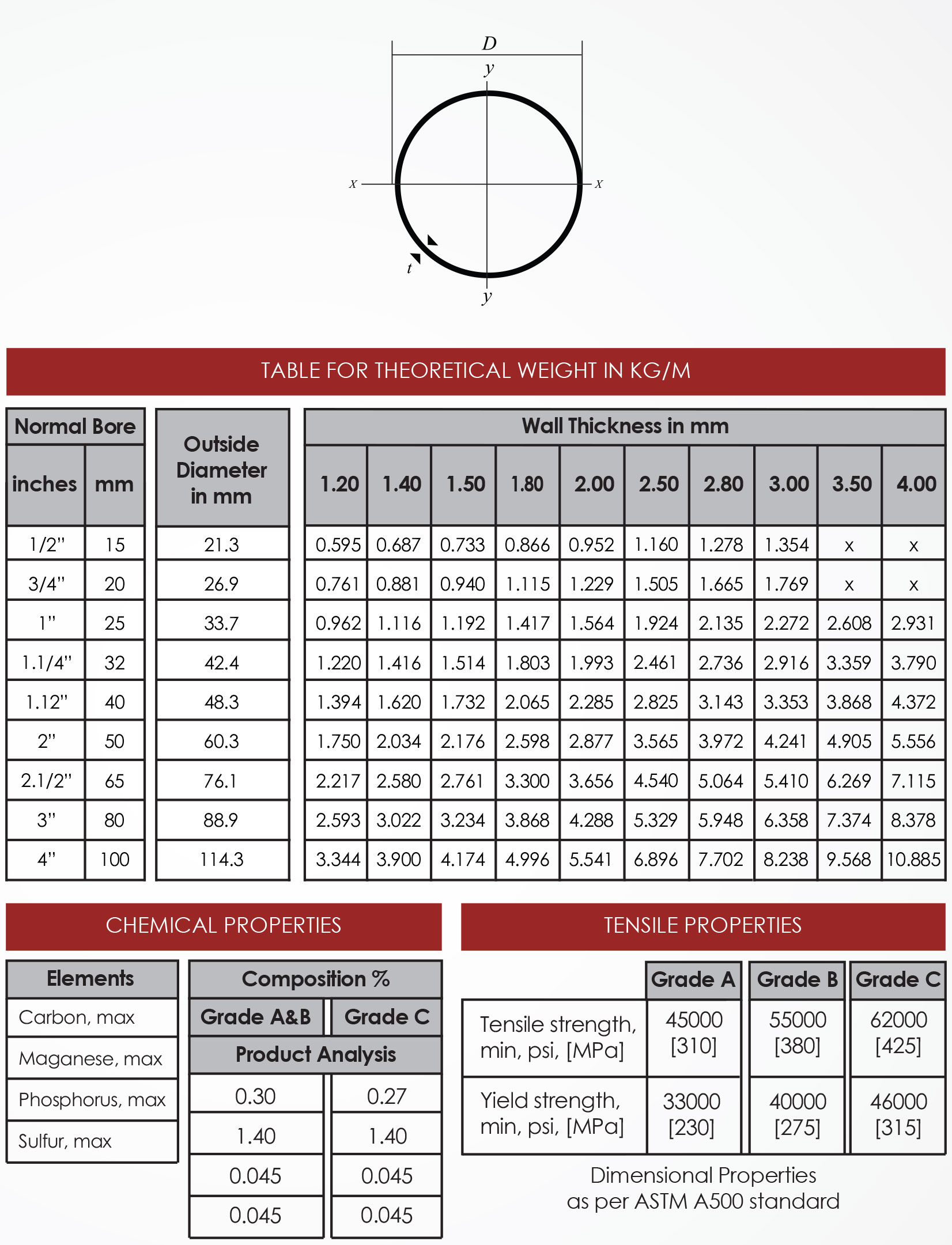

- You get normal bore ranging from 15-100 mm, with external diameters 21-114 mm respectively.

- The wall thickness ranging from 0.6-10.9 mm.

- You get grades A, B, C with tensile and yield strength ranging from 45000, 55000, 62000 psi and 33000, 40000, 46000 psi respectively.