Thanks for downloading catalogue.

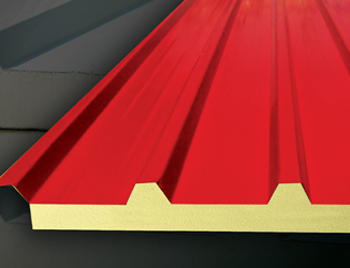

Qatar Steel Industries Factory offers painted galvanized metal panels that have Polyurethane foam, which is also known as insulated sandwich roof panels. This foam resists heat, has flame retardant properties and moisture proofing that protects the structure and its content from extreme weather conditions: staying cool during the summers, warm during the winters and dry during monsoons. Furthermore, Polyurethane has the capabilities of being flame retardant, safeguards the structure and delays fire hazards and keeps goods safe.

A structure without polyurethane sandwich panels would be susceptible to heat, cold and moisture, meaning the structure would experience extreme conditions within, that is heat, chill and dampness which are conditions that can damage perishables and making it uninhabitable. Thus sandwich panels must be procured to mitigate against said conditions.

To meet sound safety and noise pollution regulations, commercial structures such as offices and studios can benefit from the insulated sandwich panels as well. With soundproof properties, it ensures little to no sound coming and going.

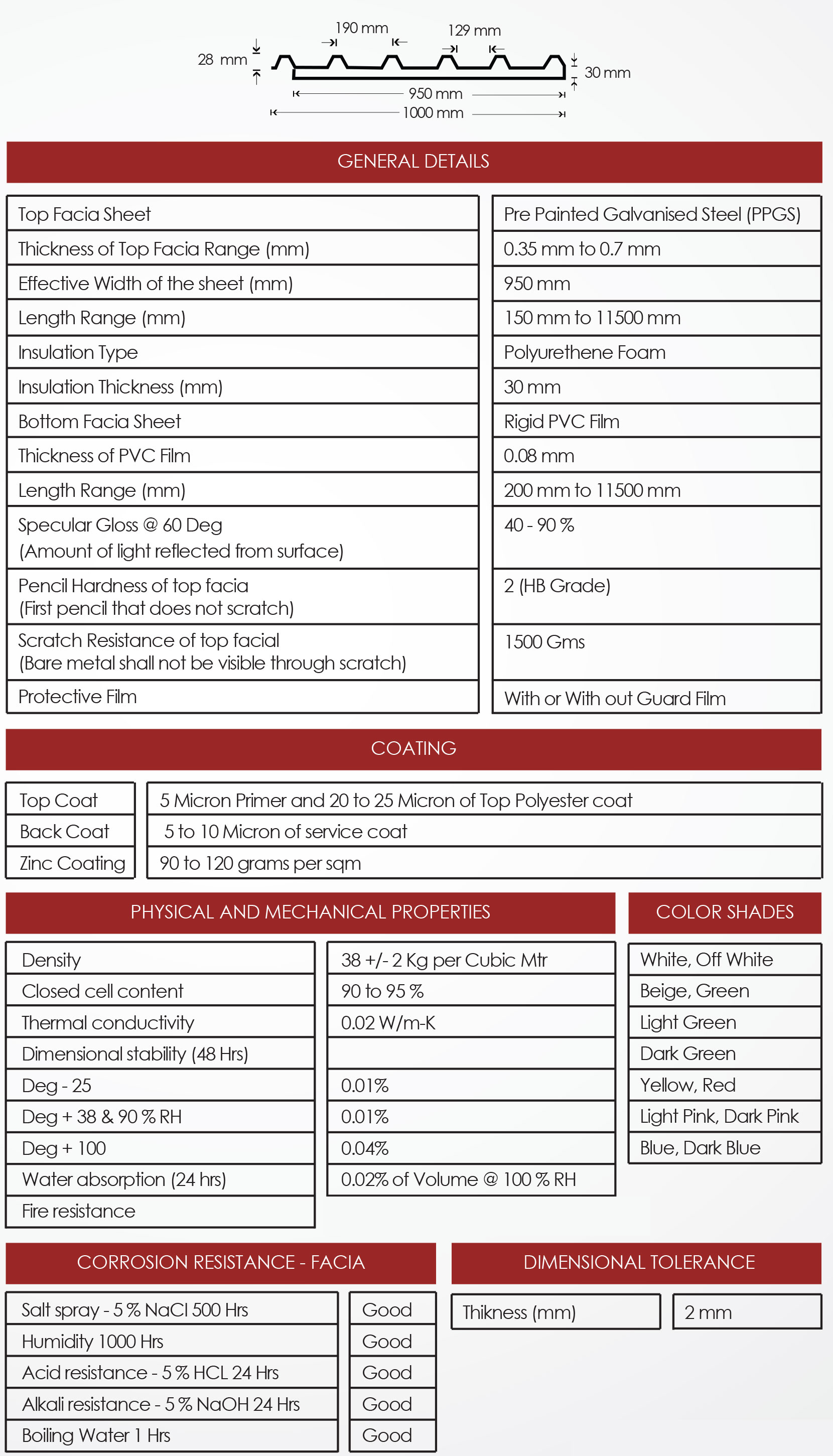

Size, Dimensions and Coating:

- Thickness ranges from 0.35mm-0.7 mm.

- The Width is 950 mm.

- Length ranges from 150mm - 11500 mm.

- A bottom fascia sheet of thickness 0.08 mm consisting of PVC.

- 1500 gms worth of scratch resistant surface.

When using Qatar Steel Industries Factory Single Skin Sandwich Roof Panel, you are guaranteed the following:

- A durable and sustainable long-lasting solution.

- Economical as the overall contracting and maintenance cost see a considerable reduction.

- Weatherproofing as the panels retain their quality in the face of harsh weather.

- Certified against fire hazards.

- Protection against moisture ensures that all things within the structure are safe from mold, rot and corrosion.

- Various style and color options open the structure to customization that is left to the client’s specifications and liking.