The Sandwich you cannot eat but still need

When considering the construction of Sheds, warehousing and cold storage steel sandwich panels are a very cost-effective choice. The same benefit can carry forward to economical spaces that can be set up quickly such as those for residential and commercial. These structures are easy to set up, durable and quite practical. Steel is durable & quite ductile, It can withstand high temperatures and heavy strain. It is light and any subsequent structural component is easy to transport and assemble. At any time if one wants to dispose of the structure, the material can be recycled without a loss to its original properties, i.e. Steel will remain steel regardless of the form it will take later.

With those attributes at their core, the steel sheets are created from cold pressing and shaped into a waveform. This particular process increases the strength and tensile properties of the sheet considerably. Furthermore, the sheets are also galvanized, where initially the sheet is zinc coated to give it the ability to resist corrosion and rusting. Thus enhancing its durability and longevity even further. The design also retains water-shedding capabilities where rain or water flows off it leaving no room for moisture buildup. These sheets also come in custom colours of paint, which act as a weather shield and add aesthetic appeal.

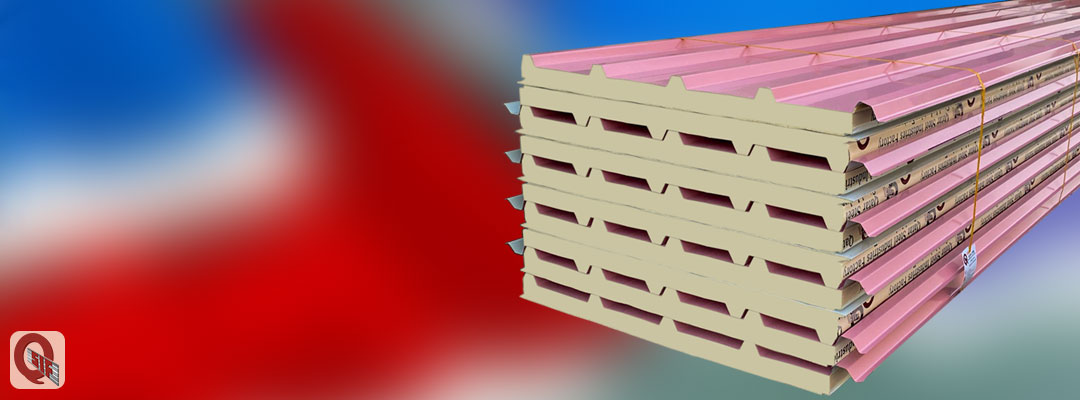

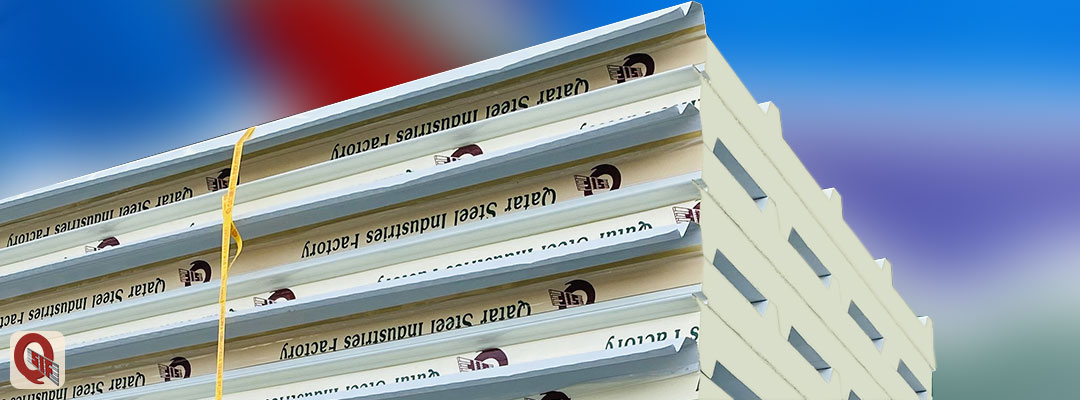

The products are further refined and broken down into three different offerings. Single Skin Sandwich Panels, Double Skin Sandwich Panels and Double Skin wall panels. The reason for these being labelled Sandwich panels is the process of sandwiching the corrugated metal between a layer of polyurethane foam. The properties of this foam are quite beneficial, where it insulates against extreme temperatures, be it hot or cold, safeguard against fire hazards, protect against mold and rot and finally dampens or soundproofs the structure.

The Single Skin Sandwich panel has one layer of Polyurethane foam that is ideal for basic warehousing of machinery, parts, dry goods, building material and even livestock. It is protected against extreme weather conditions and is ideal for regions with dry and hot weather. These panels are very cost-effective, as they need little or no maintenance, are light to transport and require little to no expertise in assembling.

The Double Skin sandwich panel has a much thicker layer of Polyurethane attached to the corrugated galvanized steel sheet. It varies in its thickness from 50 to 100mm. Due to its denser coating, the insulation against temperatures is much higher. Anything kept within a structure that has these panels installed will remain dry, warm during winters and cool during summers. It also dampens sound considerably making it ideal for offices, residential accommodations and music/recording studios.

The Double Skin Wall panel shares the same attributes as its cousin the roof panels. However, these are thicker and wider when it comes to the polyurethane foam attached. Coupled with a Double Skin Sandwich Panel one can build structures that are ideal for cold storage, warehousing for perishables and sensitive equipment. The temperature remains ambient or to whatever the installed thermostat is set to. It is also quite safe against fire hazards.