Thanks for downloading catalogue.

Qatar Steel Industries Factory specializes in manufacturing hot rolled mild steel sheets, which are used in structures, decorations, furniture, fencing, wires, automobiles and nails.

Mild steel is known for its low carbon content, due to which it is known as low carbon steel as well. The amount of carbon in mild steel varies from 0.05% to 0.25% by weight. Mild steel is not an alloy and therefore does not contain other elements apart from iron. Since it is majorly carbon and the alloying elements are relatively low, there are several properties that it possesses which differentiate it from higher carbon and alloy steels.

Carbon Steels and mild steel are quite similar in the way they are manufactured. A common method for this involves combining iron ore and coal. The coal and iron ore are melted together in a blast furnace, where then in their combined melted state they are transferred to another furnace to burn off any impurities. It is also during this process that other adjustments to the mild steel’s chemical composition can be made. Following that, the steel is allowed to solidify into a rectangular slab, which is then reduced to the desired size using processes called hot rolling or cold drawing.

Hot rolling is a process where a material is heated and processed above the recrystallization temperature. Initially, the material is usually large pieces of metal, which is fed directly into the rolling mills at a pre-defined temperature. The metal is worked, and the temperature is kept above the recrystallization state. Hot-rolled metals in their mechanical properties and deformed states have little directionality.

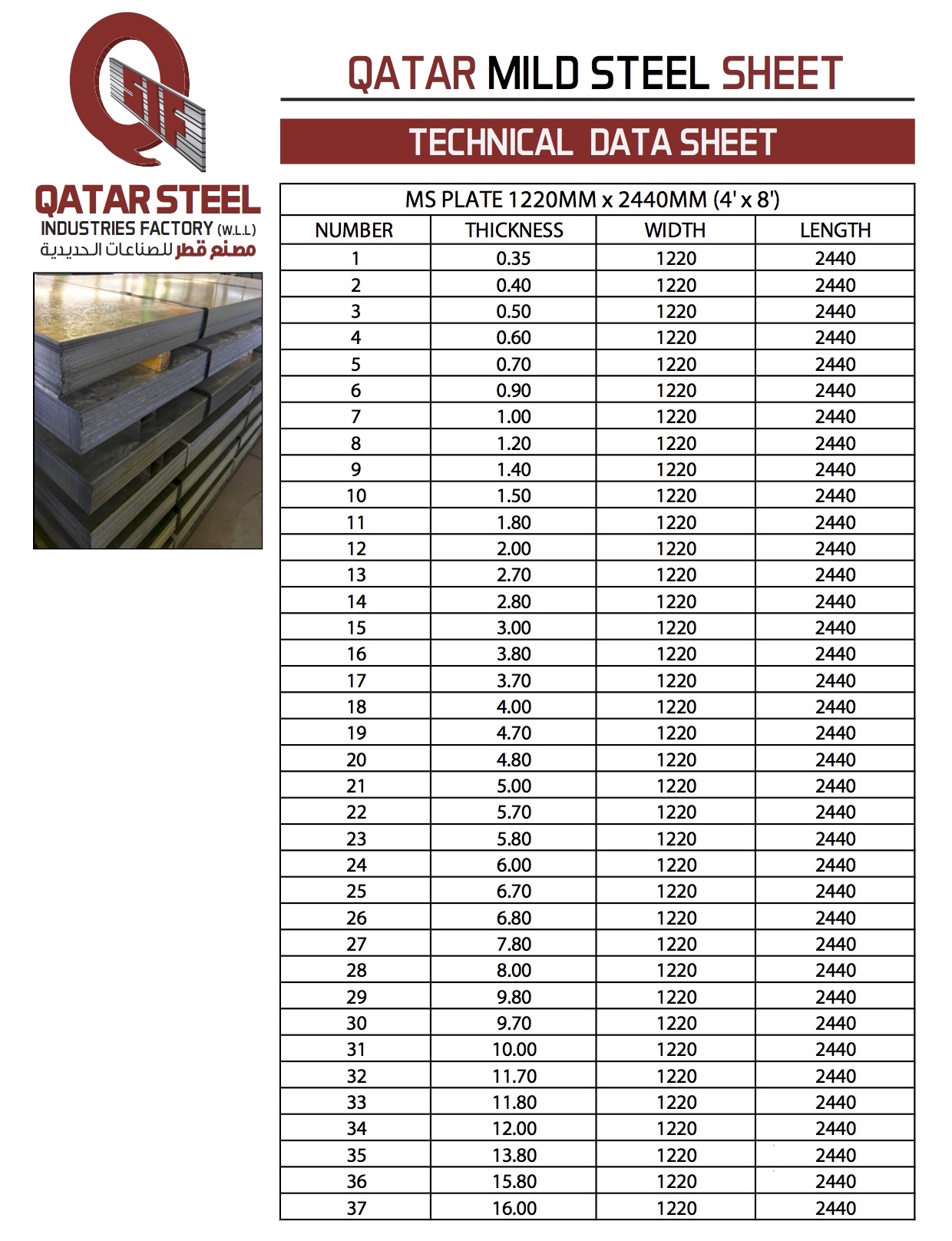

Qatar Steel Industries Factory Hot Rolled Mild Steel or MS Sheets have the following size and thickness:

- Thickness options ranging from 0.35mm - 16 mm

- Standard-length of 1220 mm and 2440 mm